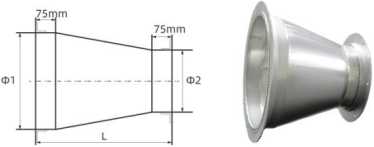

I-SUS304/ I-Teflon Coating Coating Reducer

| I-athikili No. | Ububanzi (mm) | Ububanzi (mm) | Ubude (mm) | Ubukhulu (mm) |

| RE-0100 | 100 |

|

| 0.8 (noma isicelo sekhasimende) |

| RE-0150 | 150 |

|

| 0.8 (noma isicelo sekhasimende) |

| RE-0200 | 200 |

|

| 0.8 (noma isicelo sekhasimende) |

| RE-0250 | 250 |

|

| 0.8 (noma isicelo sekhasimende) |

| RE-0300 | 300 |

|

| 0.8 (noma isicelo sekhasimende) |

| RE-0350 | 350 |

|

| 0.8 (noma isicelo sekhasimende) |

| RE-0400 | 400 |

|

| 1.0 (noma isicelo sekhasimende) |

| RE-0450 | 450 |

|

| 1.0 (noma isicelo sekhasimende) |

| RE-0500 | 500 |

|

| 1.0 (noma isicelo sekhasimende) |

| RE-0550 | 550 |

|

| 1.0 (noma isicelo sekhasimende) |

| RE-0600 | 600 |

|

| 1.0 (noma isicelo sekhasimende) |

| RE-0650 | 650 |

|

| 1.0 (noma isicelo sekhasimende) |

| RE-0700 | 700 |

|

| 1.2 (noma isicelo sekhasimende) |

| RE-0750 | 750 |

|

| 1.2 (noma isicelo sekhasimende) |

| RE-0800 | 800 |

| La01-O>2+150 | 1.2 (noma isicelo sekhasimende) |

| RE-0850 | 850 | <01 | or | 1.2 (noma isicelo sekhasimende) |

| RE-0900 | 900 | Kuncane kuno-① 1 | Kwenziwe ngokwezifiso ngokwezidingo zekhasimende | 1.2 (noma isicelo sekhasimende) |

| RE-0950 | 950 |

| Isicelo sekhasimende | 1.2 (noma isicelo sekhasimende) |

| RE-1000 | 1000 |

|

| 1.5 (noma isicelo sekhasimende) |

| RE-1100 | 1100 |

|

| 1.5 (noma isicelo sekhasimende) |

| RE-1200 | 1200 |

|

| 1.5 (noma isicelo sekhasimende) |

| RE-1300 | 1300 |

|

| 1.5 (noma isicelo sekhasimende) |

| RE-1400 | 1400 |

|

| 1.5 (noma isicelo sekhasimende) |

| RE-1500 | 1500 |

|

| 1.5 (noma isicelo sekhasimende) |

| RE-1600 | 1600 |

|

| 1.5 (noma isicelo sekhasimende) |

| RE-1700 | 1700 |

|

| 2.0 (noma isicelo sekhasimende) |

| RE-1800 | 1800 |

|

| 2.0 (noma isicelo sekhasimende) |

| RE-1900 | 1900 |

|

| 2.0 (noma isicelo sekhasimende) |

| RE-2000 | 2000 |

|

| 2.0 (noma isicelo sekhasimende) |

| RE-2500 | 2500 |

|

| 2.5 (noma isicelo sekhasimende) |

| RE-3000 | 3000 |

|

| 2.5 (noma isicelo sekhasimende) |

| RE-3600 | 3600 |

|

| 2.5 (noma isicelo sekhasimende) |

Qaphela:

I-duct diameter engaphezu kuka-2000mm iyatholakala ngokucela.

Ugqinsi lwepayipi lwakhiwe ku-SMACNA "izindinganiso zokwakhiwa kwemigudu yezimboni eziyindilinga** amakilasi 1 no-5 ngengcindezi -2500Pa (-10 in.wg) .Futhi futhi ingashintshwa njengesicelo sekhasimende.

1. Ingxenye yomzila womoya ozopendwa (kuhlanganise nendawo ye-flange engaphakathi kwepayipi) kufanele iqhunyiswe ngesihlabathi, ukuhwaqeka kwe-sandblasting kufanele kuhlangabezane nokumadladla okungu-3.0 G/S76, 40μm noma ngaphezulu, kanye nezinhlayiya zesihlabathi ezisele nothuli lwensimbi ngaphandle. ipayipi kufanele likhishwe ngemva kokuqhunyiswa kwesihlabathi.Qinisekisa ukuthi ingaphezulu le-workpiece ye-duct ihlanzekile futhi ucezu lokusebenza lumbozwe nge-aluminium foil.

2. Donsela okokufakwa kwamapayipi egumbini lokumboza, qala ukupenda, fafaza ngomshini wokumboza oyimpuphu kagesi kanye neshubhu yesibhamu esifafaziwe enwetshiwe, lungisa isikhathi se-sintering ngokusesilinganisweni ngokuya nezici zezinto ezingavuthiwe imizuzu eyi-15 ~ 20, futhi izinga lokushisa le-sintering 285°~300°C.

Ukuhlolwa kwekhwalithi engu-3.100% isiyonke (ukutholwa kogqinsi lwefilimu, ukutholwa kwembobo yephinifa), ngesihloli sokuqina kwefilimu ukuze kutholwe ukujiya kwefilimu enamathelayo.Ugqinsi lwefilimu luyi-260±30 μm.Umtshina we-pinhole usetshenziswa ukuthola ukuthi i-coating inezimbobo zokungena.Lungisa i-voltage ejwayelekile yokuthola ibe ngu-2.5KV, uma kukhona izinaliti ezidinga ukulungiswa noma kusetshenzwa kabusha.Ukujiya kwefilimu nemiphumela yokuhlola imbobo yokugoqa ngemva kokuhlolwa kwekhwalithi kufanele kurekhodwe "Kufomu Lokuhlola Ikhwalithi Ye-Duct Coatung".

4.Duct ububanzi phezu 2000mm iyatholakala ngesicelo.Ukushuba kombhobho kwakhiwe ku-SMACNA.Futhi ingashintshwa njengesicelo sekhasimende.