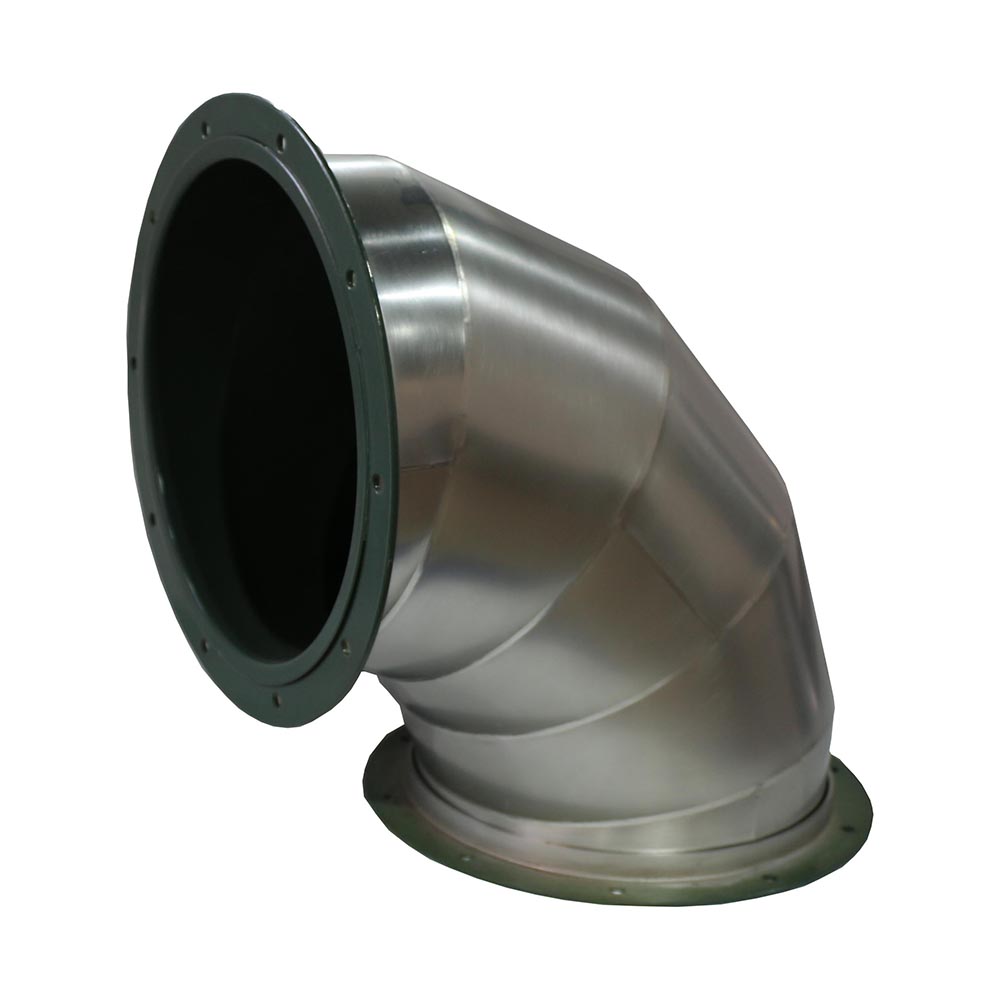

I-SUS304/ I-Teflon Coating 90° indololwane (5 Gore)

| I-athikili No. | Ububanzi (mm) | Iziqu | Irediyasi (mm) | umgodi (PC.) | Ubukhulu (mm) |

| I-E90-0250 | 250 |

|

|

| 0.8 (noma isicelo sekhasimende) |

| E90-0300 | 300 |

|

|

| 0.8 (noma isicelo sekhasimende) |

| E90-0350 | 350 |

|

|

| 0.8 (noma isicelo sekhasimende) |

| I-E90-0400 | 400 |

|

|

| 1.0 (noma isicelo sekhasimende) |

| E90-0450 | 450 |

|

|

| 1.0 (noma isicelo sekhasimende) |

| E90-0500 | 500 |

|

|

| 1.0 (noma isicelo sekhasimende) |

| E90-0550 | 550 |

|

|

| 1.0 (noma isicelo sekhasimende) |

| I-E90-0600 | 600 |

|

|

| 1.0 (noma isicelo sekhasimende) |

| E90-0650 | 650 |

|

|

| 1.0 (noma isicelo sekhasimende) |

| E90-0700 | 700 |

|

|

| 1.2 (noma isicelo sekhasimende) |

| E90-0750 | 750 |

|

|

| 1.2 (noma isicelo sekhasimende) |

| E90-0800 | 800 |

| R=01 |

| 1.2 (noma isicelo sekhasimende) |

| E90-0850 | 850 |

|

| 1.2 (noma isicelo sekhasimende) | |

| I-E90-0900 | 900 |

| R=1.5x01 |

| 1.2 (noma isicelo sekhasimende) |

| I-E90-0950 | 950 |

|

| 1.2 (isicelo sekhasimende) | |

| E90-1000 | 1000 |

|

|

| 1.5 (noma isicelo sekhasimende) |

| I-E90-1100 | 1100 |

|

|

| 1.5 (noma isicelo sekhasimende) |

| I-E90-1200 | 1200 |

|

|

| 1.5 (noma isicelo sekhasimende) |

| E90-1300 | 1300 |

|

|

| 1.5 (noma isicelo sekhasimende) |

| E90-1400 | 1400 |

|

|

| 1.5 (noma isicelo sekhasimende) |

| E90-1500 | 1500 |

|

|

| 1.5 (noma isicelo sekhasimende) |

| I-E90-1600 | 1600 |

|

|

| 1.5 (noma isicelo samakhasimende) |

| E90-1700 | 1700 |

|

|

| 2.0 (noma isicelo sekhasimende) |

| E90-1800 | 1800 |

|

|

| 2.0 (noma isicelo sekhasimende) |

| E90-1900 | 1900 |

|

|

| 2.0 (noma isicelo sekhasimende) |

| E90-2000 | 2000 |

|

|

| 2.0 (noma isicelo sekhasimende) |

Qaphela:

1. Ububanzi bombhobho obungaphezu kuka-2000mm buyatholakala ngesicelo.

2. Ukushuba kombhobho wakhiwe ku-SMACNA "izindinganiso zokwakhiwa kwamapayipi ezimboni eziyindilinga0amakilasi 1 no-5 ngengcindezi -2500Pa (-10 in.wg) .Futhi futhi ingashintshwa njengesicelo sekhasimende.

1. Ubuhlalu be-welding eqondile kufanele bushelelezi, ukuze kuzuzwe ukushisela okuhlangene ohlangothini olulodwa kanye nokwakhiwa kwezinhlangothi ezimbili, ingaphakathi kufanele licwebezeliswe bushelelezi, kungabikho ama-pores, futhi unqenqema olugoqayo lwendawo egoqayo kufanele lube flat (cishe u-90 °).

2. Ingxenye yomzila womoya ozopendwa (kuhlanganise nendawo ye-flange engaphakathi kwepayipi) kufanele iqhunyiswe ngesihlabathi, ukuhwaqeka kwe-sandblasting kufanele kuhlangabezane nokumadladla okungu-3.0 G/S76, 40μm noma ngaphezulu, kanye nezinhlayiya zesihlabathi ezisele nothuli lwensimbi ngaphandle. ipayipi kufanele likhishwe ngemva kokuqhunyiswa kwesihlabathi.Qinisekisa ukuthi ingaphezulu le-workpiece ye-duct ihlanzekile futhi ucezu lokusebenza lumbozwe nge-aluminium foil.

3. Ububanzi bombhobho ongaphezu kuka-2000mm buyatholakala uma ucelwa.Ukushuba kombhobho kwakhiwe ku-SMACNA.Futhi ingashintshwa njengesicelo sekhasimende.